Although tracked scissor lifts already existed before the advent of Almac, what makes their machine unique is its bi-levelling technology, which is found only at Almac and today installed on all their lifts. In this discussion, we aim to explore the benefits of this technology applied in various indoor and outdoor applications, particularly in terms of how its design and functional superiority can overcome limitations inherent in conventional mobile scissor lifts.

WHAT IS BI-LEVELLING SYSTEM?

The bi-levelling system enables users to surmount longitudinal slopes of up to 20° and lateral slopes of up to 15°. This functionality not only significantly increases performance, safety, and comfort but also allows users to push beyond what was previously thought possible, by auto-levelling the chassis or aerial structure even in the most extreme conditions. Now, users can easily traverse inclined terrain and other multi-level surfaces with this bi-levelling functionality, resulting in a greater return on investment. This distinctive product capability offers a simple user experience, superior market adaptability, and is well-suited to professional end-users, including arborists, or construction sectors.

HOW THIS TECHNOLOGY WORKS?

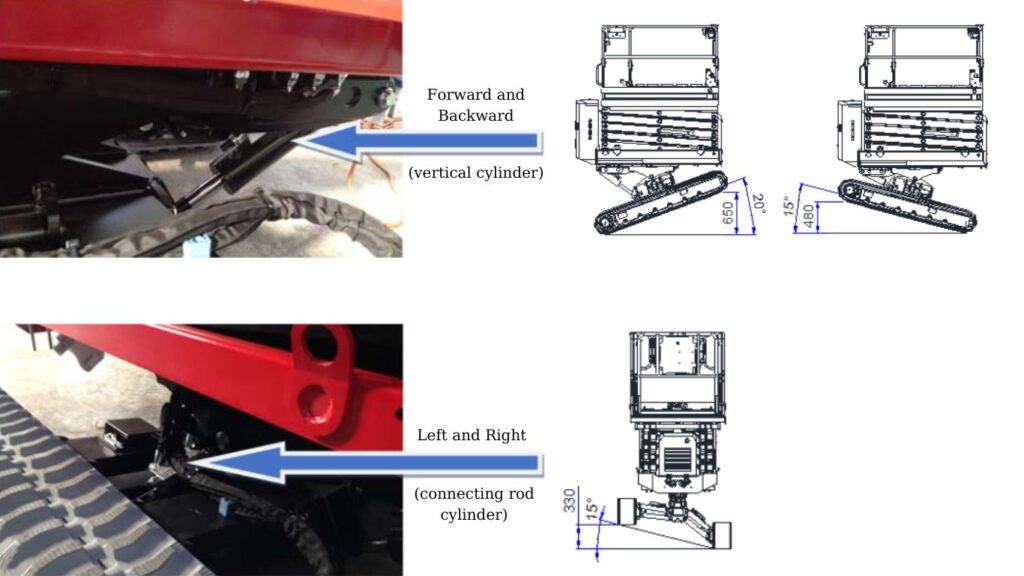

Automatic levelling is completed by three independent hydraulic cylinders that are mounted in the undercarriage.

The undercarriage has two independent bi-level legs to adjust the lateral inclination of the chassis, with a hydraulic cylinder at the rear of the undercarriage to adjust the longitudinal inclination. Utilizing independent undercarriage bi-level legs allows for unique positioning on worksites up to 20 degrees inclination. It also allows the operator, in certain circumstances, to level the machine on multi-level surfaces such as a raised concrete slab or steps.

The system will not permit lifting until the chassis is within the safety of a zero-degree level.

The safety network utilizes twin-channel inclinometers to measure the real-time inclination of the chassis, and the working height of the platform. When working, if the system detects that the elevated machine changes inclination, the alarm will sound, and further movement is restricted until the inclination is corrected.

For the EVO range, this inclination adjustment can be completed up to 6.5m working height (known as Proactive Levelling).

The platform, while it is moving, will always remain levelled and once the operating area has been reached, the machine will already be in the condition to be lifted. This function is known as Dynamic Levelling.

Not all Almac lifts come equipped with above-both levelling systems, which are optional. Please contact us for further consultation.

A major benefit of this particular technology is that the machine is designed to be safe, no matter whether it’s moving at height or stationary. As a result, the operator can concentrate on the job at hand without having to worry about manually leveling the machine, working statically, or lowering the platform for repositioning. This reduces the amount of time needed to set up the machine, leading to increased productivity for users.

Moreover, the bi-levelling technology provides increased versatility and efficiency. This technology allows the machine to be operated in areas that would typically require a more extensive setup, making it ideal for use in indoor areas with limited space or outdoor areas where the terrain can be uneven while maintaining stability, which is not present in traditional scissor lifts. The machine can be used for various purposes such as facilities maintenance, park, and tree management, council operations, building and construction, industrial and commercial plant access, tradespeople, landscapers, painters, electricians, orchardists, and primary production, including vineyards, horticulture, and agriculture.

Construction site

Park management

Landscaping

Multi-story parking lots

Power station

Tunnel

Solar panel installation

Bridge maintenance

Wall art painting

If you’re going to purchase a scissor lift, why don’t you try this unique tracked scissor lift? Do not hesitate to reach out to us at Mayon Machinery to learn more about this bi-levelling technology and how we can help you take your job versatility, efficiency, and safety.